Developed by Drivers for Drivers

Engineering, style and Functionality Merge in our flagship simulator pedals

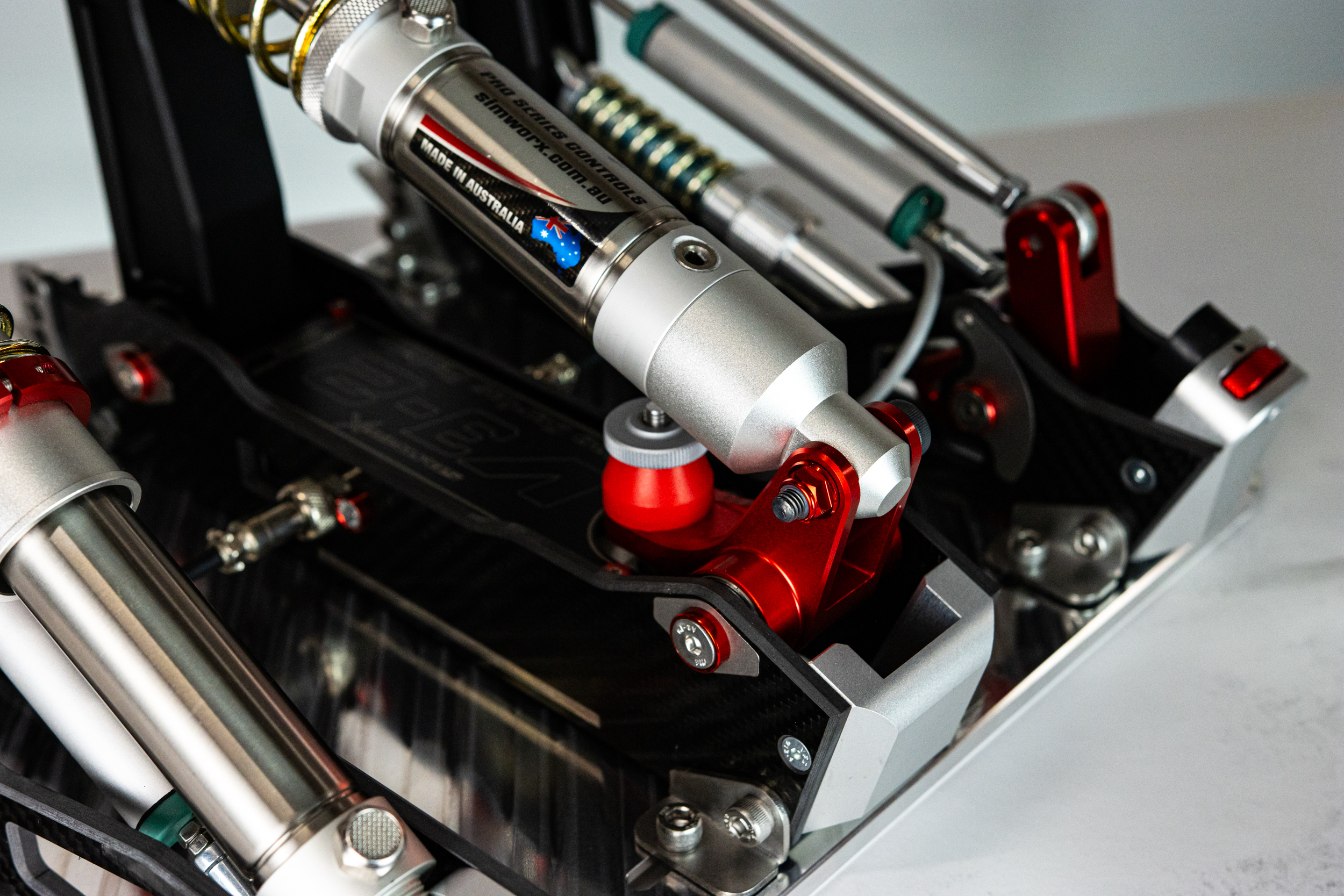

After nearly three years of development of the bespoke hardware, electronic and software components, combined with endless testing by race drivers and with our emphasis on quality engineering and design, we have finally got to the point where we can put them in to production. This Professional level pedal set, as fitted to all of our Pro Spec SX02Msport Simulators, can be used in the most demanding environments and is capable of simulating the pedal forces as experienced in V8 Supercars, GT3 and LMP-cars.

The DESIGN CONCEPTS

Supporting Firmware:

The V3.2 Simulator Pedals comes with a dedicated configuration tool – V3.2 SimControl, built in to our electronic firmware, allowing you to set up your pedals intuitively. A key feature of is the ability to set custom signal output maps per pedal. Working together with our all-new Simworx electronic interface, V3.2 SimControl allows for mapping of non-linear pedal output curves, pedal deadzones and brake pedal force. There is the ability to save an unlimited amount of profiles.

With the V3.2 Simulator Pedals being able to cope with very high brake loads, a sturdy mount to your simulator rig is an absolute must. For that reason we supply a billet CNC Machined Base Plate to mount the pedal modules on to. The V3.2 Baseplate allows flexible and rock solid positioning of the individual pedals.

Minimising Operating Noise.

All the V3.2 Pedals have noise dampening built in to their front and rear stops to reduce user noise. This is especially designed to minimise any noise in domestic situations. The front stops on all pedals have dampening as long as there is load on them. If the stop is wound in too far, i.e not in contact with the base, the dampening effect will not work. If the pedal angle is not to your liking, there are adjustable mounting brackets to angle it to your desired foot placement. The adjustable pedal stops can then fine tune the pedal to your final optimum position.

Baseplate

This Billet CNC Machined baseplate creates a solid platform to mount the V3.2 Pedals to on your own simulator platform. The brake of the V3.2 Pedals is able to cope with up to 140kg of force, the standard mounting plates of non Simworx rigs may show excessive flex under these loads so you may need to reinforce your sim rig if this occurs.

Mounting Hardware

You also receive mounting hardware for the pedals. The pedal plate mounting points for the pedals are slots, these slots allowing lateral adjustment of individual pedals. The slots are recessed underneath the base to house the mounting nuts which fit flush to the underside of the base. They can slide easily, allowing easy adjustment even when the base is hard mounted to a flat surface.

The dimensions of these lateral slots are 110mm for the brake and 80mm for the throttle and clutch. The Mounting Slots on each side of the pedal base allows for easy fitment to any rig including alloy extrusion rigs and allows adjustability forward or back so you can attain perfect pedal positioning.

The Simworx V3.2 Pedals Baseplate will also fit directly on to earlier SIMWORX SX02Msport Chassis systems.

Features:

- Independent Pedal Carriers

- Three Pedal set in Billet 6061 Aluminium and Carbon Fibre

- All Stainless Steel Bolts

- Simworx dedicated V3.2 SimControl supporting firmware for unlimited adjustability

- Sealed Ball Bearing Pivot Points

- CNC machined Carbon Fibre Pedal Carrier Sides

- Billet 6061 CNC Machined Pedal Uprights

- Load Cell Brake Technology

- CNC Machined Components throughout

- Adjustable Brake Preload

- CNC Rocker Arm Brake Activation

- Over Centre Loaded Clutch

- Adjustable Clutch Pressure

- Adjustable Accelerator Pedal Stroke

- Adjustable Accelerator Pedal Spring Rate

- Billet CNC Anodised Pedal Pads with Carbon Fibre Pad inserts

- Adjustable Clutch Pedal Pad

- Fully adjustable Brake Pedal Pad

- 140kg maximum Brake pressure

- Dedicated Simworx Electronic Interface

- Dedicated Simworx Firmware

- Adjustable Heel Rest

- Anodised Finish on all CNC Components

- USB Plug & Play

What’s Included

1 x Simworx Pro GT V3.2 Pedal Set

1 x Simworx Pro GT Heel Rest

1 x A to B USB Cable

1 x Stainless Steel Bolt Pack

1 x User Manual

1 x Tool Set